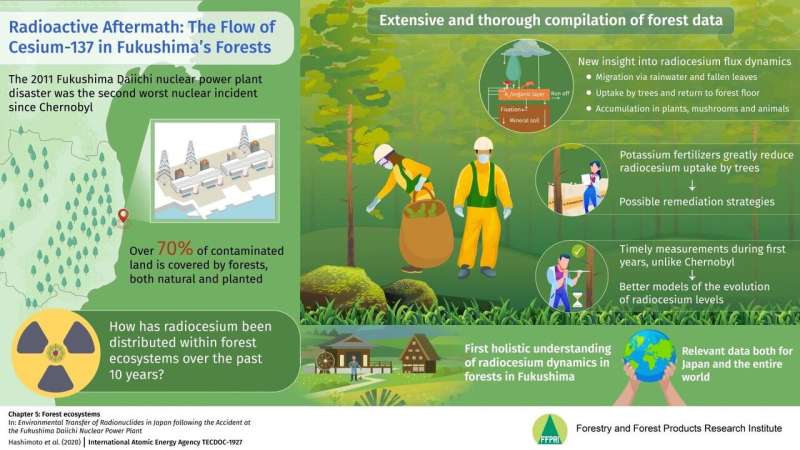

....Considering the massive threat posed by 137Cs to the health of both humans and ecosystems, it is essential to understand how it has distributed and how much of it still lingers. This is why the International Atomic Energy Agency (IAEA) has recently published a technical document on this specific issue. The fifth chapter of this "Technical Document (TECDOC)," titled "Forest ecosystems," contains an extensive review and analysis of existing data on 137Cs levels in Fukushima prefecture's forests following the FDNPP disaster.

The chapter is based on an extensive study led by Assoc. Prof. Shoji Hashimoto from the Forestry and Forestry Products Research Institute, Japan, alongside Dr. Hiroaki Kato from the University of Tsukuba, Japan, Kazuya Nishina from the National Institute of Environmental Studies, Japan, Keiko Tagami from the National Institutes for Quantum and Radiological Science and Technology, Japan, George Shaw from the University of Nottingham, UK, and Yves Thiry from the National Agency for Radioactive Waste Management (ANDRA), France, and several other experts in Japan and Europe.

The main objective of the researchers was to gain a better understanding of the dynamics of 137Cs flow in forests. The process is far from straightforward, as there are multiple elements and variables to consider. First, a portion of 137Cs-containing rainfall is intercepted by trees, some of which is absorbed, and the rest eventually washes down onto the forest floor. There, a fraction of the radiocesium absorbs into forest litter and the remainder flows into the various soil and mineral layers below. Finally, trees, other plants, and mushrooms incorporate 137Cs through their roots and mycelia, respectively, ultimately making it both into edible products harvested from Fukushima and wild animals.

Considering the complexity of 137Cs flux dynamics, a huge number of field surveys and gatherings of varied data had to be conducted, as well as subsequent theoretical and statistical analyses. Fortunately, the response from the government and academia was considerably faster and more thorough after the FDNPP disaster than in the Chernobyl disaster, as Hashimoto explains: "After the Chernobyl accidents, studies were very limited due to the scarce information provided by the Soviet Union. In contrast, the timely studies in Fukushima have allowed us to capture the early phases of 137Cs flow dynamics; this allowed us to provide the first wholistic understanding of this process in forests in Fukushima."