Annals of Work Exposures and Health Vol 61 Issue 1 is now available online. The contents list with links to free abstracts is provided below. The full text of the Editor's Choice, editorial, review and commentary are free to access online on the following link: https://academic.oup.com/annweh/issue.

Jan 31, 2017

Annals of Work Exposures and Health Vol 61 Issue 1 is now available online - free abstracts

Annals of Work Exposures and Health Vol 61 Issue 1 is now available online. The contents list with links to free abstracts is provided below. The full text of the Editor's Choice, editorial, review and commentary are free to access online on the following link: https://academic.oup.com/annweh/issue.

Jan 30, 2017

Process Safety News - Winter 2017

Winter 2017 Process Safety News!

This issue includes:

REVISITING REACTIVE VAPOR SYSTEMS VENT SIZING

Hans K. Fauske, D.Sc., Regent Advisor, Fauske & Associates, LLC

QUALITATIVE FIRE RISK ASSESSMENT USING NFPA® 550, NFPA® 551 AND THE FIRE SAFETY CONCEPTS TREE

James A. Huddleston, P.E., Senior Consulting Engineer, Fauske & Associates, LLC

REVISTING CHERNOBYL - 30 YEARS LATER

AnnMarie Fauske, Customer Outreach & Digital Media Manager, Fauske & Associates, LLC

NEW IN FLAMMABILITY: THE DISCOVERY HYBRID RHEOMETER

Megan Piotrowski, Lab Chemist, Fauske & Associates, LLC

THREE CRITICAL OVERSIGHTS THAT PRECEDE COMBUSTIBLE DUST INCIDENTS

Tim Cullina, MS, PE, Senior Safety and Environmental Consulting Engineer

& Ursula Malczewski, Chemical Engineer, Fauske & Associates, LLC

On-The-Job Deaths At Highest Level Since 2008

Jack Benton, CDS: A total of 4,836 deaths due to workplace injuries occurred in 2015 – a 0.3 percent increase over 2014 and the most since 5,214 workers died in 2008, according to data released Dec. 16th, 2016 by the Bureau of Labor Statistics.

Other highlights from the 2015 Census of Fatal Occupational Injuries:

- The 903 deaths among Hispanic or Latino workers and 495 deaths among African-American workers were the most since 2007 and 2008, respectively.

- 650 deaths occurred among workers age 65 and older – the second-highest total among this demographic since the Census of Fatal Occupational Injuries began in 1992.

- Roadway incident fatalities climbed 9 percent to 1,264, accounting for 26 percent of all fatal work-related injuries in 2015.

- The private construction industry recorded 937 deaths, the highest total since 975 in 2008.

- Heavy and tractor-trailer truck drivers experienced 745 fatal injuries, the most of any occupation.

- Fatal injuries among private oil and gas extraction workers were 38 percent lower in 2015 than 2014.

- The states with the highest number of worker deaths were Texas with 527, followed by California with 388, Florida with 272 and New York with 236.

Although the overall rate of fatal workplace injuries fell to 3.38 per 100,000 in 2015 from 3.43 per 100,000 in 2014, the rise in the number of fatalities alarmed officials.

"These numbers underscore the urgent need for employers to provide a safe workplace for their employees as the law requires," Secretary of Labor Thomas Perez said in a press release. "We have a moral responsibility to make sure that workers who showed up to work today are still alive to punch the clock tomorrow."

Meanwhile, AFL-CIO Director of Safety and Health Peg Seminario sounded a warning for the future. "The bottom line is that working people in this country need more safety and health protection – not less," Seminario said in a statement. "The new administration's actions on worker safety will be an important measure of whether they are keeping their campaign promises to improve the lives of workers."

Sources: Jack Benton, CDS

Jan 27, 2017

EPA announces a Public Meeting on Collecting Chemical Use Information

On February 14th, EPA will hold a public meeting to receive public input and information on uses and conditions of use for the initial ten chemicals to be evaluated under the Toxic Substances Control Act (TSCA), as amended by the Frank R. Lautenberg Chemical Safety for the 21st Century Act. Information on uses and the conditions of use will assist EPA in identifying potential exposure scenarios for the ten chemicals. The meeting will be held on February 14, 2017 from 9:00 a.m. to 3:00 p.m., at the Ronald Reagan Building and International Trade Center, Polaris Room, 1300 Pennsylvania Avenue Northwest, Washington, DC 20004. To participate, please register online: https://tscachemicaluse.eventbrite.com The meeting will also be available by remote access for registered participants. EPA has also established public dockets for those who wish to submit information. Written comments and materials will also be accepted and should be submitted before March 1, 2017. For additional information, including links to the public dockets, please visit: https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/evaluating-risk-existing-chemicals-under-tsca

FREE Webinar & Lunch: EPA RMP - THE FINAL RULE: How does this affect your facility?

PSRG Inc. will hold a special PSM/RMP Forum Luncheon Series from January 18, 2017 to February 22, 2017 in various locations. You are cordially invited to attend the program that is most convenient for you. There is no fee to attend this event. A complimentary buffet lunch will be provided.

After more than three years of review and iterations on proposed modifications to the RMP Rule (40 CFR 68), EPA announced on December 21 the long-awaited FINAL RULE. The 372-page final rule bolsters new requirements for third party audits, incident investigations, emergency preparedness and response, and information sharing which will affect every covered facility.

In a recent decision, the Fifth Circuit vacated OSHA citations issued to Delek Refining Co. in 2008 for the alleged failure to correct PHA and audit findings that had been conducted by the prior owner of the facility prior to its acquisition by Delek. The PHAs at issue were completed in 1994, 1998, 1999, and 2004, and the audits dated back to 2001 and 2004. In vacating the citation items, the Court unanimously rejected OSHA's argument that the alleged failures were continuing violations that extended the six month statute of limitations contained in the OSH Act.

The guest speaker will be Mr. Mark S. Dreux, a nationally recognized expert attorney in occupational safety and health law and partner at Arent Fox LLP in Washington, DC. Mr. Dreux's presentation will discuss the EPA's new RMP Rule, how it impacts your business, and the necessary steps and timeline to comply.

U.S. Chemical Safety Board (CSB) released a safety video of its investigation of the June 13, 2013 explosion and fire at the Williams Olefins Plant in Geismar, Louisiana

January 26, 2017, Washington, DC – The U.S. Chemical Safety Board (CSB) released a safety video of its investigation of the June 13, 2013 explosion and fire at the Williams Olefins Plant in Geismar, Louisiana, which killed two workers and injured an additional 167. The deadly explosion and fire occurred when a heat exchanger containing flammable liquid propane violently ruptured.

The CSB's newly released 12-minute safety video entitled, "Blocked In," includes a 3D animation of the explosion and fire as well as interviews with CSB investigator Lauren Grim and Chairperson Vanessa Allen Sutherland. The video is based on the CSB's case study on the Williams incident and can be viewed on the CSB's website and YouTube. Chairperson Sutherland said, "Our investigation on the explosion at Williams describes an ineffective process safety management program at the plant at the time of the incident. We urge other companies to incorporate our recommendations at their facilities and to assess the state of their cultures to promote safety at all organizational levels to prevent a similar accident. " The CSB's investigation found many process safety management program deficiencies at Williams, which set the stage for the incident. In particular, the CSB found that the heat exchanger that failed was completely isolated from its pressure relief valve. In the video, Investigator Lauren Grim said, "When evaluating overpressure protection requirements for heat exchangers, engineers must think about how to manage potential scenarios, including unintentional hazards. In this case, simply having a pressure relief valve available could have prevented the explosion."

CLICK HERE TO WATCH THE NEW SAFETY VIDEO: http://www.idevmail.net/link.aspx?l=6&d=86&mid=414620&m=1816

Jan 26, 2017

WISCONSIN - Pharmaceutical pollution takes toll on crayfish and other species

By Carin Tunney at Great Lakes - Drugs seeping into groundwater threaten crayfish and have a domino effect of environmental impacts that harm fish and other species, according to new research.

Pharmaceutical pollution happens when medicines are improperly disposed or flushed into septic tanks and sewers as the body eliminates them, said Paul Moore, an ecologist from Bowling Green State University's Laboratory for Sensory Ecology.

Treatment can't filter them so they make their way into lakes and streams, he said.

Moore recently published research that shows even at low levels, a popular headache medicine has a negative environmental impact. His research exposed crayfish to naproxen, an over-the-counter pain medication.

And that's bad news for many other aquatic species faced with pollution from pharmaceuticals.

Crayfish are a keystone species, one that many others species depend upon, Moore said. If they died, so would trout and bass. That would lead to algae overgrowth and in turn, insects and invertebrates would die when decaying algae used up all the oxygen.

Moore's research was prompted when anglers reported fewer crayfish in Burt Lake in Cheboygan County, Michigan. Although the observations were not scientific, Moore decided to evaluate the potential threat of pharmaceutical exposure to crayfish survival.

He placed crayfish into simulated streams made of cinderblocks at the University of Michigan's Stream Research Facility in Pellston, Michigan. The streams had a constant flow that mimicked a natural river, he said.

The study found the naproxen made the crayfish less aggressive, Moore said.

"What is unique is that [crayfish] fight all the time, and the fighting determines who gets food, who gets shelters, who gets mates, " he said. "Depending on the different concentrations of the exposure, we saw different effects on their fighting behavior."

Moore said the reduction of aggression is likely because naproxen impacts the crayfish's sense of smell. Smell sends their brains cues about critical elements of survival.

"When they start to fight, they release chemical signals back and forth, and inside these signals are anything from the sex of the animal to the reproductive state, even a type of identity so they know if they fought this guy yesterday or the day before," he said. "So if you block that ability . . . they fight more intensely or less intensely based on the amount of exposure they have."

Moore focused on naproxen because he said non-prescription drugs are the fastest growing source of pharmaceutical pollution.

Other research shows hormones and antidepressants also harm species, including fish.

This type of research raises alarm for people, said Lyman Welch, the legal director for Alliance for the Great Lakes, an advocacy group based in Chicago.

"The effects on fish and aquatic life can be a real indicator of concern for humans," he said. "The fact that pharmaceuticals harm fish can act as a canary in a coal mine and give us a warning that we need to pay more attention."

Forty-million people rely on the Great Lakes for drinking water and recreation, Welch said.

"There is no known [human] health risk at the low levels of the chemicals that are being found right now, but our detection levels have improved, and we are starting to see these chemicals." Welch said. "And there is a need to do additional research to better understand the impacts of these chemicals."

Alliance for the Great Lakes supports forcing pharmaceutical companies to help pay some of the cost for disposal. Only nine counties throughout the U.S. require drug companies to pitch in, but the laws are changing, Welch said.

Cook County, Illinois, approved an ordinance last November that requires pharmaceutical companies to pay for some of the disposal cost. The buy-back program forces those who sell medications to register with the county and pay a fee for disposal. The ordinance has a provision that penalizes the drug producers if they pass the cost on to consumers.

Counties in California and Washington have similar laws.

But Welch said most programs rely on consumers to safely dispose of medications.

The Tip of the Mitt Watershed Council in Petoskey, Michigan, helped organize safe drop-off sites for unused drugs within four-counties in Northern Michigan, said Executive Director Gail Gruenwald. The project is funded by grants from local community foundations, the Michigan Department of Environmental Quality, the Environmental Protection Agency and others.

It is a coordinated effort by pharmacies, hospitals and law enforcement. Prescription medications, including narcotics, can't be left in an unsupervised dropbox and law enforcement must transport controlled substances to disposal sites.

Over the last nine years, residents turned in 12 tons of waste, including prescription drugs, over-the-counter medications and beauty supplies, Gruenwald said.

"At this point there are not solutions for removing pharmaceuticals once they are in lakes and streams. So this is a prevention issue," she said. "We need to keep it out of the waterways."

Please read full By Carin Tunney at Great Lakes Echo: http://greatlakesecho.org/2017/01/25/pharmaceutical-pollution-takes-toll-on-crayfish-and-other-species/

Use EPA’s Safer Choice label to make better purchasing decisions

Finding products that are safer for you, your employees, your family, and the environment should be easy. That's why EPA developed the new Safer Choice label. Products with the Safer Choice label help consumers and commercial buyers identify products with safer chemical ingredients, without sacrificing quality or performance.

Finding products that are safer for you, your employees, your family, and the environment should be easy. That's why EPA developed the new Safer Choice label. Products with the Safer Choice label help consumers and commercial buyers identify products with safer chemical ingredients, without sacrificing quality or performance.

More than 2,000 products currently qualify to carry the Safer Choice label. You can find products for your home at retail stores, as well as products to use in facilities like schools, hotels, offices, and sports venues.

Participation in the Safer Choice program is voluntary. Companies that make products carrying the Safer Choice label have invested heavily in research and reformulation to ensure that their products meet the Safer Choice Standard. These companies are leaders in safer products and sustainability.... EPA has more information here.

Why Walmart’s $250 Billion Pledge Will Make US Manufacturing More Sustainable

VIA Jessica Lyons Hardcastle at Environmental Leader The Walmart US Manufacturing Innovation Fund has invested about $3 million in projects that aim to make domestic manufacturing more cost-effective and sustainable, bringing its grants awarded total to $10 million.

The fund, which launched in 2014, is a collaboration between Walmart, the Walmart Foundation and the United States Conference of Mayors. It focuses on making it both easier and more competitive to manufacture household goods in the US. It's also part of the retail giant's larger commitment to invest $250 billion in American manufacturing by 2023.

An estimated 1 million new US jobs will be created through Walmart's manufacturing initiative, according to the Boston Consulting Group.

An earlier Innovation Fund investment, for example, went to Cornell University, which developed a textile recycling technology that turns post-consumer textiles into new products and also reduces energy and water consumption in the process.

In its third and final round of grants, announced yesterday, the Innovation Fund has awarded about $3 million to six research and academic institutions.

The grant recipients were selected for their ability to address two key challenges to domestic manufacturing:

- Reducing the cost of textile manufacturing, including home textiles and apparel, in the US by addressing obstacles throughout production.

- Improving common manufacturing processes with broad application to many types of consumer products.

Please read full by Jessica Lyons Hardcastle at Environmental Leader

Zero Waste is Within Our Reach, But….

Via EPA Blog -By Sarah Levinson I would have guessed that my fellow EPA employees would be leaders when it comes to recycling and reducing wastes. Turns out we are leaders, but not quite as far out front as I had hoped. In 2015, a presidential Executive Order on Sustainability directed federal agencies to do their best to divert at least half our non-hazardous wastes into recycling and composting, and to work our darnedest to reach zero waste. While we  at EPA's New England office have indeed succeeded in diverting more than half our waste to recycling and compost, our regional office has yet to achieve net-zero waste (defined as sending at least 90 percent of our waste to recycling or composting) despite our best efforts. We, like many other organizations, face many of the same challenges when it comes to modifying our own behavior.

at EPA's New England office have indeed succeeded in diverting more than half our waste to recycling and compost, our regional office has yet to achieve net-zero waste (defined as sending at least 90 percent of our waste to recycling or composting) despite our best efforts. We, like many other organizations, face many of the same challenges when it comes to modifying our own behavior.

My job has been to help my colleagues make the "green choice" when managing wastes they generate in the office. By working with a small team of dedicated volunteers, the Green Team as we are known, instituted a composting program and we have done extensive education and outreach to promote both recycling and composting. We have put out recycling guides and compost guides, posted clear signage showing usual items for composting as well as recycling, held informational sessions, provided tips for preventing waste in the first place, and demonstrated the impact that compost amended soil can have on moisture retention and plant growth. We have also reduced paper communications and urged employees to carry reusable shopping bags, even providing the bags in our lobby. We tried to tap into the competitive spirt, running a contest between offices to see which office could divert the most from the trash stream.

Even with all of these activities and ever since we instituted composting which greatly boosted to our diversion rate, our diversion rate seems to have become stagnant. After some thought about this challenge, the Green Team decided that in order to keep improving, we needed to know what was being thrown into our trash. Specifically, we sought to identify "contaminants" that shouldn't be in the trash.

Consequently, and timed to coincide with America Recycles Day Nov. 15, The Green Team undertook a messy, but

Most of the waste in our trash containers bound for the landfill should have been recycled or composted.

detailed one-day waste audit. Eight dedicated sorters separated 44 pounds of trash in about two hours. To our surprise, although staff had composted and recycled 75 percent of their unwanted materials, we found that two thirds of the material thrown in the trash could still have been recycled or composted. There were apple cores, banana and orange peels, paper bags, plastic containers and glass bottles all in the trash, when these things could have and should have been placed in recycling or the compost collection. It turned out that only a third of the material in the trash was truly trash and furthermore, we found that had staff properly sorted these items, we could have met the goal of zero waste for that day!

So while we didn't attain our zero waste goal on Nov. 15, we now know that zero waste is well within our reach. Additionally, because we took many pictures of the "contamination" found in our trash, we now are using the photos to conduct targeted education and outreach. We hope that for many, "seeing" the poor choices that they made will turn them into "believing" the errors of their ways and modify their behavior accordingly. Additionally, by looking closely at was in our trash, we are able to strategize and discuss new ideas to implement to further reduce our waste.

I know that the Green Team will persevere with new ideas, and new efforts to guide and motivate behavioral change. I know that the Green Team won't give up our quest and am confident that it is just a matter of time until we attain our zero waste goal, becoming true leaders in living a more sustainable lifestyle, especially because we have shown it to be possible.

Please follow: EPA Blog

Looking for a contract Safety Inspector for 12 weeks at night on Downtown Milwaukee Wisconsin project

Jan 25, 2017

Arizona experts want better tracking methods for drugs in your water

How to Best Manage Pharmaceutical Waste

New Zealand Bans Make-up with plastic beads

Smith today announced that cosmetic products containing tiny plastic particles known as microbeads would be banned in July next year because of concerns about their impact on the marine environment.

The move was welcomed by scientists, though they said New Zealand had been slow to act and further reduction of other plastics was needed. Environmentalists want the Government to go further by banning or taxing plastic bags.

Smith said the Government was targeting microbeads because they could not be recycled and because there was clear evidence of harm to waterways, fish and shellfish.

"There is no practical way that a New Zealander can take the microbeads in these products and somehow sieve them out and prevent them from getting into the marine environment," he said at a press conference in Wellington this afternoon.

"There is not the evidence in New Zealand that a substantive portion of the plastic bags that we use in shopping and other uses end up in the marine environment."

Smith said he would not rule out changes in relation to plastic bags in future, but the Government's focus was currently on a nationwide recycling scheme.

The United States and Canada have already begun the process of banning microbeads, and Australia has threatened a ban if companies do not voluntarily remove them from their products.

New Zealand's cosmetics industry said bans imposed by overseas countries meant most large manufacturers were already phasing out microbeads. Cosmetic Toiletry and Fragrance Association executive director Garth Wyllie said products containing microbeads would be "long gone" from shelves by the time New Zealand's ban came into force.

However, Smith said he was surprised by the number of products containing microbeads which were still available.

"I note that some companies have already announced that their intention is to phase them out. I was surprised today, despite those commitments, seeing a very wide range of dozens and dozens of products, everything from shampoos to face cleaners to shaving creams to sunscreen and toothpaste containing these microbeads."

Cosmetics giant The Body Shop said plastics such as polyethylene were no longer used in any of the company's products. Managing director of the New Zealand branch, Barrie Thomas, said the company replaced the beads with natural alternatives between 2014 and 2015.

Scientists with an interest in microplastics praised the Government's move while urging further action.

University of Canterbury senior lecturer Sally Gaw, from the Department of Chemistry, said microplastics were of concern because they were widespread in oceans and had been found in an increasing number of marine animals.

The Government's ban was a "great step forward", she said.

"Further steps will be required to reduce the enormous volume of plastics entering our oceans each year."

University of Auckland associate professor Mary Sewell, from the School of Biological Sciences, said New Zealand was "behind the rest of the world" because many countries had already banned the products.

'NO SENSE' IN USING PLASTIC

Environment Minister Nick Smith announced the ban this afternoon at a press conference in Wellington.

"The problem with microbeads is that they are too small to retrieve or recycle, they do not biodegrade, and that they are mistaken by marine life as food, causing long-term damage to aquatic animals and like fish and mussels," Smith said.

"The use of plastic microbeads in personal care products like facial cleaners and toothpaste makes no sense when there are biodegradable alternatives like apricot kernels and ground nut products that achieve the same results."

The plastic beads were first used in medical treatment, and the ban is unlikely to extend to medical products.

Companies who continued to sell products containing microbeads faced a maximum fine of $100,000.

EPA - Modernizing the Risk Management Plan Rule

With this in mind, I'm proud to announce that EPA modernized the accidental release prevention requirements under the Clean Air Act, also known as our Risk Management Program (RMP). This rule is a crucial component of EPA's efforts to enhance the safety and security of chemical facilities nationwide. Safer facilities can save the lives of facility workers, first responders and nearby community residents. For example, these finalized amendments will help avoid accidents, such as the explosions at the Chevron Richmond refinery in 2012 and at West Texas Fertilizer in 2013.

In the Report for the President (June 2014) on implementing Executive Order 13650, Improving Chemical Facility Safety and Security (August 2013), we envisioned amending existing RMP regulations by 2016. The amendments were signed on December 21, 2016, and are available online at: https://www.epa.gov/rmp/final-

This rule is based on discussions and feedback spanning three years of across-the-board engagement with industry and first responders, as well as community leaders, local, tribal and state governments, environmental organizations, and other stakeholders – more than 1,800 participants in over 25 states. Taking input from first responders, facility owners and operators, state, local and tribal partners, and community members, we developed a broad request for information in 2015 and a proposed rule in February 2016. Since then, we have narrowed the proposal, after listening to concerns raised, for example the increased costs and workload to industry and first responders, security concerns regarding the public availability of information, and the need to focus on evacuation and shelter-in-place planning. This rule moves our efforts to enhance chemical facility safety forward, while listening to input from around the nation.

One contributing factor to chemical accidents is a lack of effective coordination between facilities and local emergency responders on the chemical risks at the facility. One of the most important benefits of the rule is to clarify who has response lead and who has the equipment to respond. Increasing coordination and establishing appropriate response procedures can help reduce the effects of accidents and save lives. That's why we're requiring annual coordination. Facilities must conduct notifications, field and tabletop exercises, and invite local responders to participate.

We are committed to preserving facility security while enabling communities to protect themselves. That's why the final rule strikes a balance between communities' right-to-know, for the sake of first responder, community and employee safety, and facility security concerns, for the sake of business confidentiality and broader, homeland security issues. Responders and community members can request appropriate facility chemical hazard information while allowing protection of sensitive information that could be misused. This can significantly improve community emergency preparedness and allow emergency planners to develop effective evacuation and shelter-in-place procedures.

Under this rule, facility owners/operators will better analyze why accidents happen and determine what they can do to prevent future accidents. Incident investigations will include accident and near-miss root-cause analyses. Facilities will hire an independent third-party to conduct a compliance audit of facility processes after an accident occurs, and hold a public meeting within 90 days of an RMP reportable accident so communities can talk with facility representatives directly.

Finally, facilities in chemical, petroleum/coal products, and paper manufacturing sectors will take a hard, serio

https://blog.epa.gov/blog/

Trump Administration Freezes Regulations, Hiring, and U.S. EPA Grants/Contracts; Issues Executive Order on Pipeline and Project Reviews

Michael Best & Friedrich LLP: On January 20, 2017, President Trump's Chief of Staff, Reince Priebus, released a memorandum to all heads of Executive Departments and agencies ordering them to halt or freeze all pending regulations for 60 days in order to ensure that the President's appointees or designees have the opportunity to review any new or pending regulations.

Regulations that have been sent to the Office of the Federal Register (OFR) but have not been published are immediately withdrawn from the OFR for review and approval by the President's appointees or designees. Regulations that have been published in the OFR but have not taken effect are temporarily postponed for 60 days pending review and approval. Regulations that affect critical health, safety, financial, or national security matters are excluded from the freeze, as determined by the Director of the Office of Management and Budget. A list of 30 U.S. Environmental Protection Agency (EPA) regulations which are immediately subject to the freeze can be found here.

The purpose of the regulatory freeze is to allow President Trump's administration to review pending regulations and guidance. The freeze does not necessarily ensure the regulation's ultimate demise.

President Trump also issued an executive action freezing hiring for the federal workforce (with exemptions for the military and positions of national security or public safety). He has also directed the U.S. EPA to freeze issuing grants and contracts which would impact states and companies that rely upon them. The U.S. EPA's grants are used to support infrastructure and other environmental activities. The U.S. EPA's contracts are currently valued at over $6 billion and are wide-reaching.

Pipelines and Project Reviews

On January 24, 2017, President Trump issued four memoranda and an executive order concerning the construction of pipeline projects and review of infrastructure projects. The presidential memoranda set forth the following directives:

- Construction of Keystone XL Pipeline: Invites TransCanada Keystone Pipeline, L.P. to promptly re-submit its application for a cross-border permit and directs the State Department to issue a decision within 60 days.

- Construction of the Dakota Access Pipeline: Directs the Secretary of the Army to instruct the Assistant Secretary of the Army for Civil Works and U.S. Army Corps of Engineers to consider whether to withdraw the Obama administration's Notice of Intent to prepare a new environmental impact statement on the project.

- Construction of American Pipelines: Directs the Secretary of Commerce to develop a plan for all new, repaired, and expanded pipelines in the U.S. to use steel and other materials made in the U.S., to the maximum extent permitted by law. The Secretary of Commerce shall submit the plan to the President within 180 days.

- Streamlining Permitting and Reducing Regulatory Burden for Domestic Manufacturing: Directs departments and agencies to expedite reviews and approvals for proposals to construct or expand manufacturing facilities through reductions in regulatory burdens affecting domestic manufacturing. The Secretary of Commerce shall submit a report to the President setting forth a plan to streamline the federal permitting process and reduce regulatory burdens for domestic manufacturers.

The President's Executive Order, "Expediting Environmental Review and Approvals for High Priority Infrastructure Projects", streamlines and expedites environmental reviews and approvals for all infrastructure projects, especially projects that are a high priority for the U.S., such as improving the electrical grid and telecommunications systems and upgrading ports, airports, pipelines, bridges, and highways. The Chairman of the White House Council on Environmental Quality shall decide whether an infrastructure project qualifies as a "high priority" project within 30 days of a request. The Executive Order also calls for the relevant agency heads to establish expedited procedures and deadline for environmental reviews and approvals for high priority projects.

Jan 23, 2017

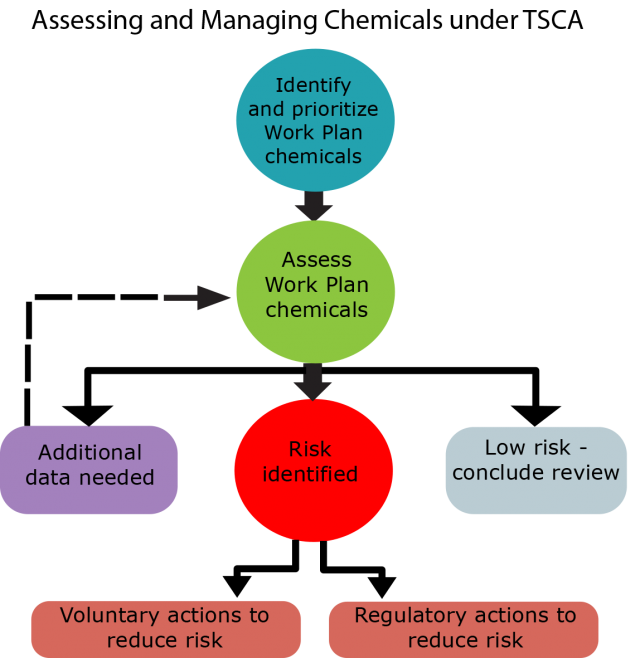

How EPA Assesses Chemical Safety for Toxic Substances Control Act (TSCA)

EPA is using a multi-pronged strategy to ensure the safety of chemicals in commerce, recognizing that the current chemicals management law, the Toxic Substances Control Act (TSCA) of 1976, needs to be strengthened.

EPA's three part strategy for addressing potential risks from existing chemicals includes:

- Identifying chemicals for assessment and taking actions as appropriate;

- Increasing opportunities for industry to move toward using safer chemicals; and

- Increasing public access to data on chemicals that have been developed by EPA and/or provided by industry

In September 2009 EPA issued Essential Principles for Reform of Chemical Management Legislation to help inform efforts underway in Congress to reauthorize and significantly strengthen the effectiveness of TSCA.

The following graphic provides an overview of the process EPA uses to assess and manage TSCA chemicals in commerce.

Read full: https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/how-epa-assesses-chemical-safety

Jan 19, 2017

FREE - Suicide Prevention Summit on February 1st - Oak Brook,IL

Members of CFMA Chicago Chapter in partnership with the Builders Association have organized the Suicide Prevention Summit. This half-day collaboration between construction and mental health professionals, will explore suicide prevention for the construction industry. By targeting construction industry CEOs, CFOs, Human Resource professionals, and Safety and Risk managers, this event will provide a wealth of knowledge to professionals in the industry.

According to Dr. Sally Spencer-Thomas, CEO and Co-Founder of the Carson J Spencer Foundation, clinical psychologist, mental health advocate, faculty member, and survivor of her brother's suicide, "In this male-dominated industry, the stoic, macho 'tough guy' culture creates barriers to seeking help and acknowledging emotional problems."

Summit attendees will connect with community mental health professionals, find out what their industry peers are doing on this issue, and amass resources to help promote mental health and suicide prevention as part of their companies' overall health initiatives.

Along with Spencer-Thomas, Bob Swanson and David Sauerman will share their experiences and how suicide has affected their lives.

Time: 2 - 5 PM Summit

5 PM Networking reception with food & drink

Place: Maggiano's Little Italy, 240 Oakbrook Center,

This event is free to participants, thanks to the generous support of Blue Cross Blue Shield of Illinois and both the construction and behavioral health communities. Register for this free program.

Jan 18, 2017

EPA Issues Final Rule Amending Risk Management Program

(PAINT.ORG) The U.S. Environmental Protection Agency (EPA) published finalized amendments to the Risk Management Program (RMP) Rule in the Jan. 13 Federal Register. According to EPA, the amendments made to the final rule were aimed at modernizing RMP by (1) making changes to the accident prevention program requirements, (2) enhancing the emergency response and preparedness requirements, and (3) modifying the information availability requirements. The final rule will be effective on March 14, 2017.

In general, EPA's RMP program applies to all stationary sources with processes that contain more than a threshold of a regulated substance. The program's elements are intended to prevent accidental releases and reduce the severity of releases that occur. All sources must prepare and submit an RMP to EPA at least every five years. In addition, RMP Program 3 facilities involve processes subject to OSHA's Process Safety Management (PSM) Standard or are in one of the specified NAICS codes, such as chemical manufacturing. Together, PSM and RMP form the regulatory framework for prevention of catastrophic chemical accidents at fixed facilities.

During the rulemaking process last year, ACA submitted comments to EPA in response to numerous changes it proposed to make to the RMP program. A number of ACA companies have facilities subject to RMP requirements, particularly Program 3 facilities which have the most stringent requirements. ACA's main concern with the RMP proposal is that the proposed changes would not actually enhance chemical facility safety, but would instead create significant administrative burdens and higher compliance costs without commensurate benefits in safety. EPA acknowledged in the final rule that it did take each comment received into consideration, but several of its proposed amendments withstood the criticism and remain in the final rule.

ACA will be hosting a webinar for members on January 25, 2017 from 1:00-2:30 PM (EST) to discuss the substantial changes to the RMP. Please contact ACA's Rhett Cash for registration and any other information.

Specific amendments to each area include the following.

Accident Prevention Program Requirements

Amendments made to the accident prevention program requirements include changes to the incident investigation and accident history requirements, modifications to third party audit requirements, and alterations to the safer technology and alternatives analysis (STAA) requirements.

Incident Investigation and Accident History Requirements

The RMP final rule requires additional reporting elements to investigations that are required after any incident that resulted in or could reasonably have resulted in a catastrophic release (i.e., a "near miss"). The facility must identify the fundamental reason ("root cause analysis") for the incident, and prepare a report within 12 months of the incident that includes consequences of the accident and any emergency response actions taken.

Third-Party Audit Requirements

This provision requires an independent third party to conduct a compliance audit at a facility if there has been a reportable accident, or if an implementing agency determines that a third-party audit is necessary (based on information about the facility or about a prior third-party audit at the facility). The final rule also contains criteria for auditor competence and independence. In addition, the owner or operator must engage a third-party auditor, and complete the audit within 12 months of when either (a) an implementing agency determines that conditions at the facility could lead to an accidental release of a regulated substance; or (b) a previous third-party audit failed to meet the competency or independence criteria specified in the rule. Lastly, the third-party audit may be conducted by a third-party auditor or a team of auditors led by a third-party auditor.

Safer Technology and Alternatives Analysis (STAA) Requirements

The RMP final rule modifies the process hazard analyses (PHAs) provisions to require certain industry sectors with Program 3 processes (including the chemical manufacturing sector) to conduct a safer technology and alternatives analysis and to evaluate the practicability of any inherently safer technologies or designs. The STAA must be included in the PHA report, and refers to risk reduction strategies developed using a hierarchy of controls that are considered inherent, passive, active, and procedural.

Emergency Response and Preparedness Requirements

Amendments made to the emergency response preparedness requirements include changes to the local responders' coordination requirements and modifications to facility exercise requirements.

Local Responders Coordination Requirements

The RMP final rule increases coordination with Local Emergency Planning Committees (LEPCs) to enhance local emergency preparedness and response planning by requiring facilities to conduct annual coordination with LEPCs or local emergency response officials to clarify response needs, emergency plans, roles, and responsibilities. Qualifying facilities must develop an emergency response plan, develop procedures for the use, inspection, and testing of emergency response equipment, conduct training for employees in relevant procedures, and update the emergency response plan to reflect changes at the facility. Furthermore, the owner or operator of a facility must coordinate response needs with local emergency planning and response organizations to determine how the facility is addressed in the community-wide emergency response plan and to ensure that local response organizations are fully aware of the regulated substances at the facility, their quantities, the risks presented by covered processes, and the resources and capabilities at the facility to respond to an accidental release of those substances. Lastly, the final rule requires the owner or operator to review and update the emergency response plan when appropriate based on changes at the facility or new information obtained from coordination activities, emergency response exercises, incident investigations, or other available information.

Facility Exercise Requirements

The final rule requires qualifying facilities to perform notification exercises and to perform tabletop and field exercises. The owner or operator must consult with local officials to establish an appropriate frequency for field and tabletop exercises, with a minimum timeframe of one notification exercise per year, one tabletop exercise every three years, and at least one field exercise every 10 years.

Read full at: (PAINT.ORG)

Ban on powdered gloves coming Jan. 18 FDA cites numerous health dangers

Powdered medical gloves are going the way of powdered wigs.

A once ubiquitous staple of doctors, powdered gloves are being thrown out of exam and operating rooms by the U.S. Food and Drug Administration as of Jan. 18. The reason: The powder poses a variety of risks to wearers, patients and even bystanders.

The dangers include severe airway inflammation from inhaling the powder; wound inflammation and post-surgical adhesions from contact with the powder; and respiratory allergic reactions from breathing powder that carries proteins from natural rubber latex gloves. The most common type of powder used in gloves is cornstarch, according to the FDA.

The coming ban is absolute — there's no grace period for using up existing supplies. "[T]he risks of illness or injury to individuals who are currently exposed to these devices is [as] equally unreasonable and substantial as it would be for future individuals that might be exposed to powdered gloves," the FDA stated in a March 22, 2016, Federal Register notice proposing the ban. The ban was made final on Dec. 19.

Although glove use in veterinary medicine is not explicitly mentioned in the FDA rule, the prohibition applies in the veterinary sphere, too, an agency spokeswoman confirmed.

"The ban applies to powdered surgeon's gloves, powdered patient examination gloves, and absorbable powder for lubricating a surgeon's glove that are already in commercial distribution and for these devices that are already sold to the ultimate user, such as small medical practices and hospitals. As such, it applies to ... gloves that are in use at veterinary practices," the spokeswoman, Deborah Kotz, said by email.

Asked how the ban will be enforced, Kotz replied: "The FDA can take various enforcement actions, if necessary, to remove banned devices from the market, including seizure of the product, civil money penalties or criminal prosecution."

She declined to say what criminal charges could be brought, or the potential size of fines.

The FDA recommends unused inventories of gloves be disposed of like any community solid waste, which usually is by burial in a landfill or by incineration.