HoustonChronicle - Poor planning and a series of cascading equipment failures led to dangerous chemicals erupting into flame in late August during the height of Hurricane Harvey. The miscalculations indicate the company's lack of preparation for more than 3 feet of flooding, reflected by an emergency management plan that barely addressed how to handle such a storm.

Those judgments led to the burning of nine trailers containing the company's stockpile of organic peroxides. The resulting inferno exposed first responders and local residents to dangerous fumes and pulled emergency staffers away from hurricane recovery at a critical time.

Arkema officials argue that unprecedented floods made it impossible to prevent its chemicals from catching fire. The site had only seen up to 2 feet of flooding in the past, company officials said.

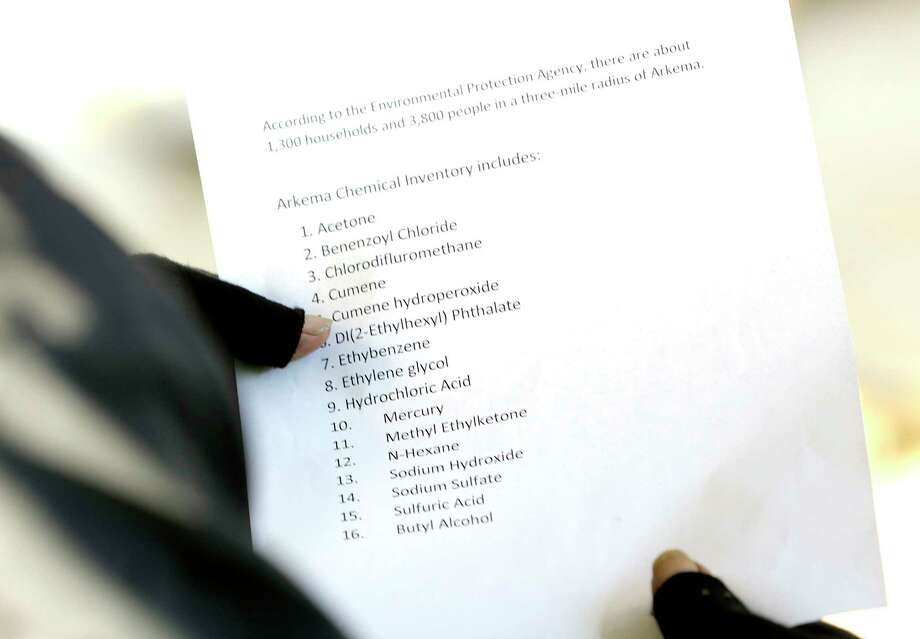

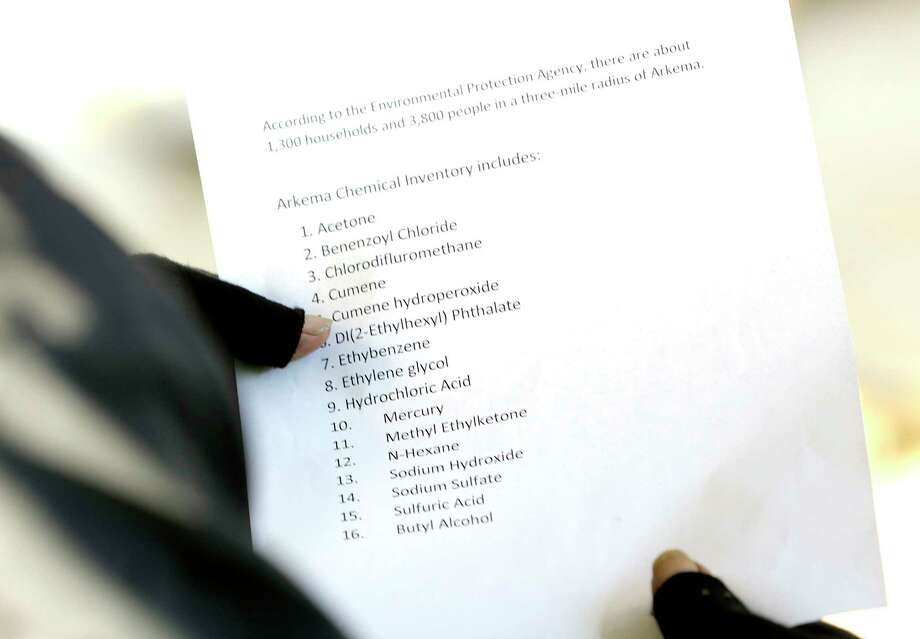

Photo: Elizabeth Conley, Houston Chronicle

A list of chemicals at the Arkema plant was passed around to people who live near the chemical plant on Saturday, Nov. 11, 2017, in Crosby.

The Chronicle obtained Arkema's internal records from the U.S. Environmental Protection Agency and conducted interviews with government employees with knowledge of ongoing investigations of the events at the plant. The emerging picture reveals nine days of chaos, culminating with the decision to intentionally burn chemicals that posed a danger to the public.

The records, obtained through the Freedom of Information Act, and interviews show that:

Arkema's emergency response plan provided employees with little direction for how to handle major flooding events. It contained one paragraph about flooding but a page and a half on handling bomb threats, records show.

Arkema's main power transformers and its powerful backup generators were not high enough off the ground, causing them to become submerged with floodwaters, Arkema records show. Without power, the company could not keep its stash of organic peroxides at a safe temperature inside its refrigerated buildings.

The company's last resort for keeping organic peroxides cool - refrigerated trailers - also was destined to fail. The diesel-powered trailers had fuel tanks that ran along the bottom of the vehicle. More than 3 feet of water compromised the fuel tanks, causing the freezers to die.

Arkema had a tank of an extremely dangerous chemical, isobutylene, located about 40 yards from six trailers that had been relocated during the storm, according to interviews and satellite images. Government officials were concerned about a chain reaction with that chemical that could have led to catastrophic results.

Arkema officials said again Tuesday that no amount of planning could have protected its site from the storm.

"Many of your conclusions fail to recognize that Hurricane Harvey was unlike any rain event Houston ever experienced," company spokeswoman Janet Smith said in an email. "FEMA's 500-year flood map doesn't address the situation that occurred during Hurricane Harvey."

Four days after Harvey made landfall in Texas, the Arkema plant was under 7 feet of water. The last employees to evacuate the site left by boat, floating over a 6-foot chain-link fence topped by barbed wire, the records show.

"Flooding in Houston is a perfectly foreseeable event," said Paul Orum, an independent Washington, D.C., consultant and longtime chemical safety advocate. "Facilities should be prepared when it comes to several different layers of flooding."

Lines laid low

Arkema, a French multinational company, manufactures chemicals used to create plastic products. Many of its proprietary compounds are classified as organic peroxides, which must be kept at temperatures well below freezing to prevent the chemicals from catching fire.

With Hurricane Harvey bearing down on Southeast Texas and the National Hurricane Center warning of potentially "catastrophic" or "life-threatening" flooding, the company's plans for protecting its product were simple: keep the chemicals cold on-site.

The company had multiple freezer buildings, six backup generators, and, as a last resort, refrigerated trucks. Documents provided to the Chronicle did not indicate any plans to drive the organic peroxides away from Harvey's impact.

But Arkema's plan for Harvey was based on one flawed assumption: that the site would never experience floods higher than 3 feet. By the end of the weekend, the rain had exceeded that total.